Sealing seams

Sealing the joint is one of the most important stages of construction work, because it is through weak points in structures that moisture most often penetrates, which leads to the destruction of concrete and a reduction in the service life of the structure. To achieve long-term protection, it is important to follow the technology and use special materials that have been proven in practice. One of the most effective solutions is the use of hydro-dowels.

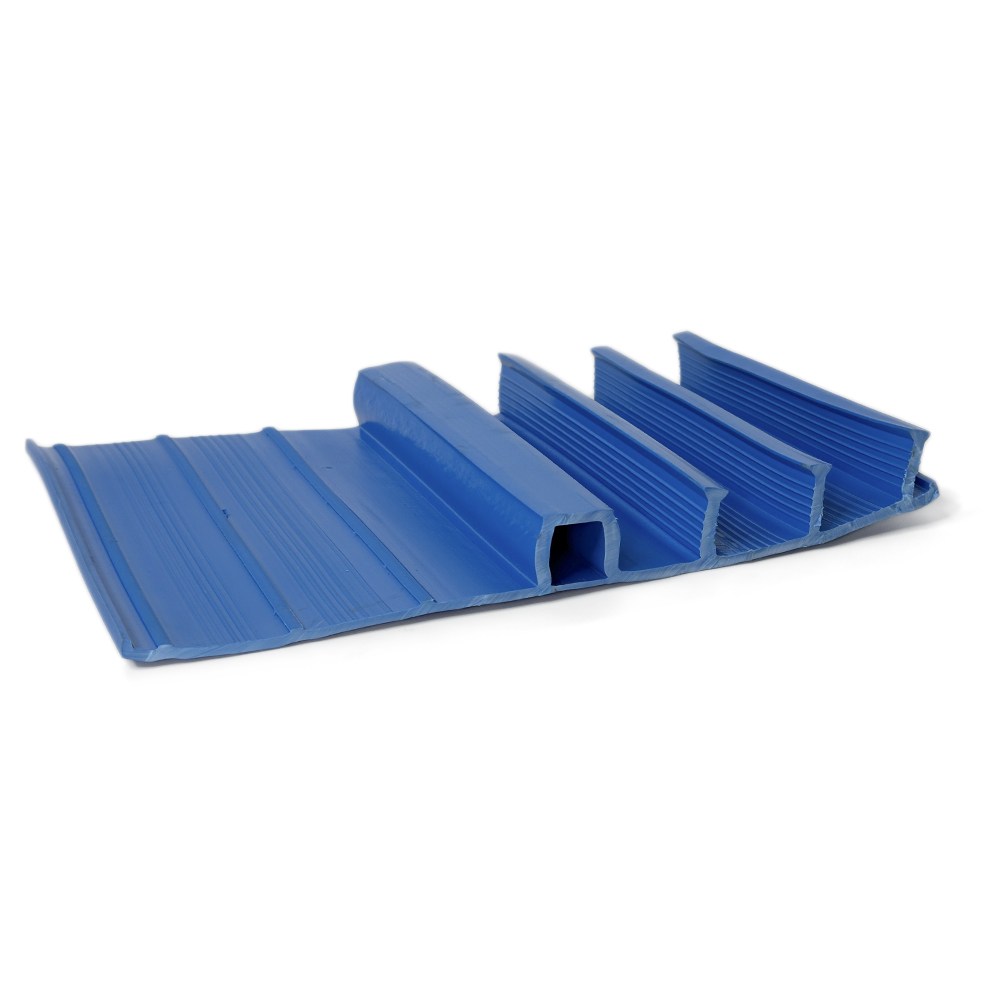

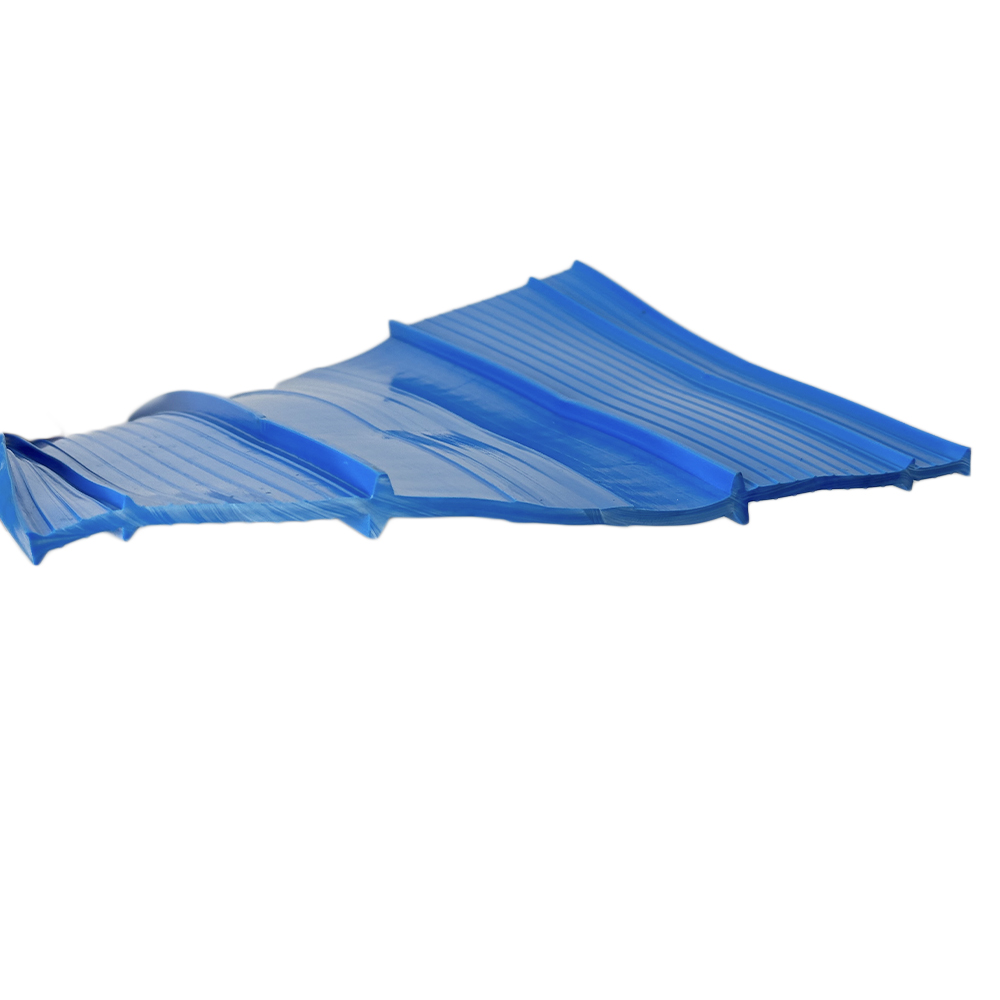

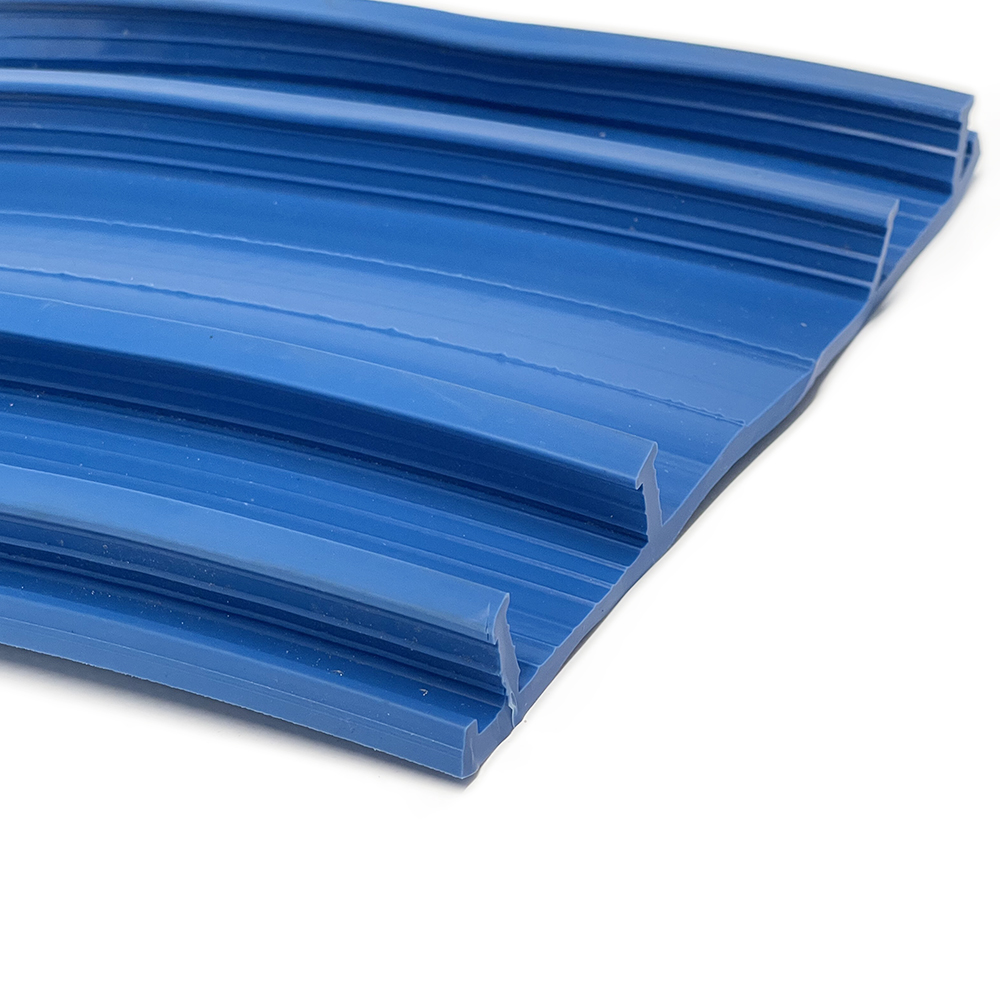

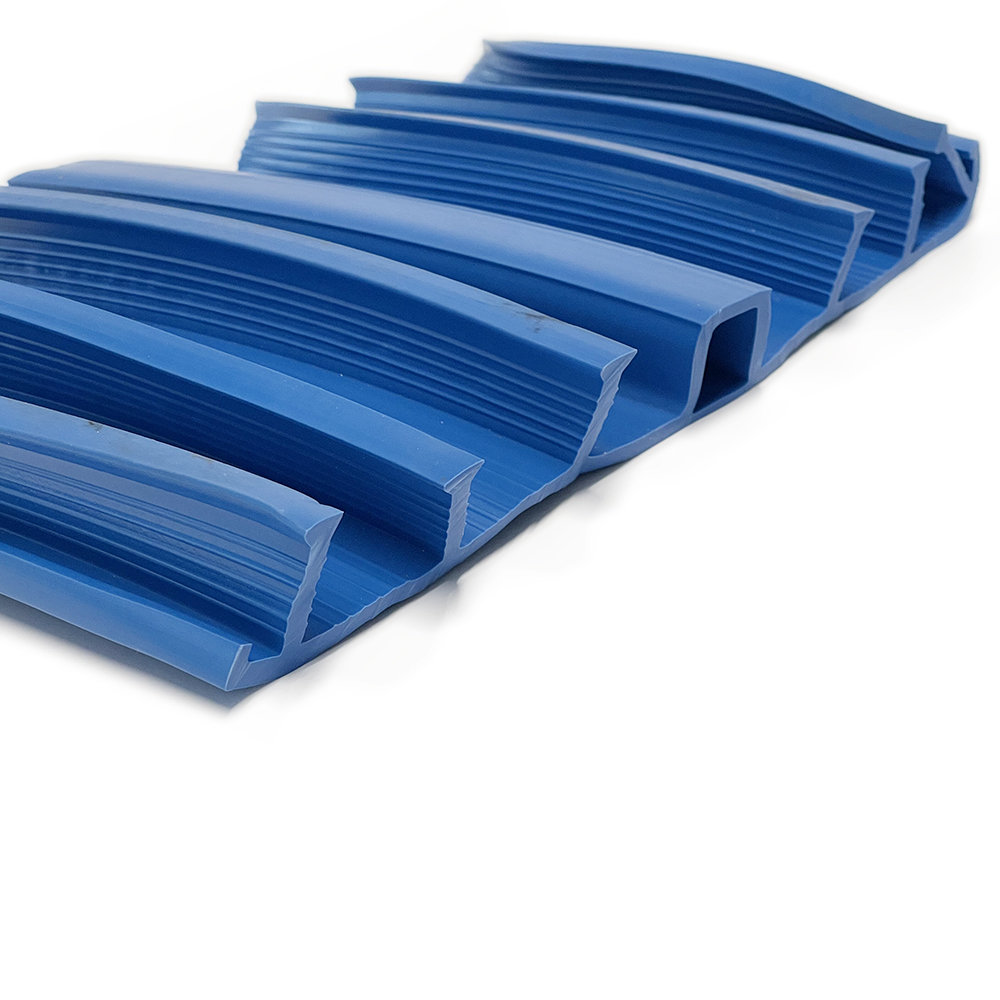

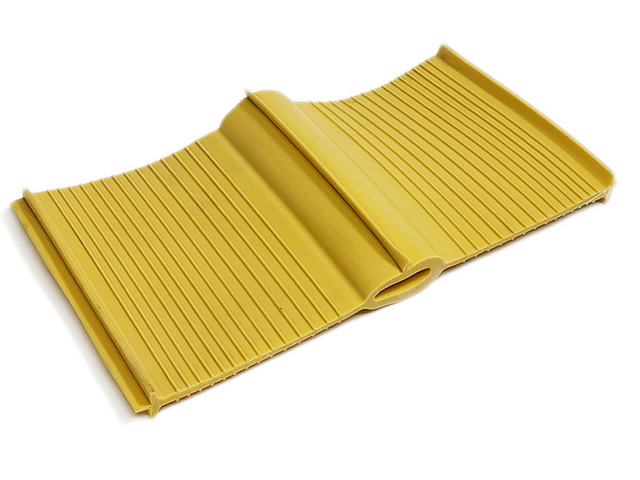

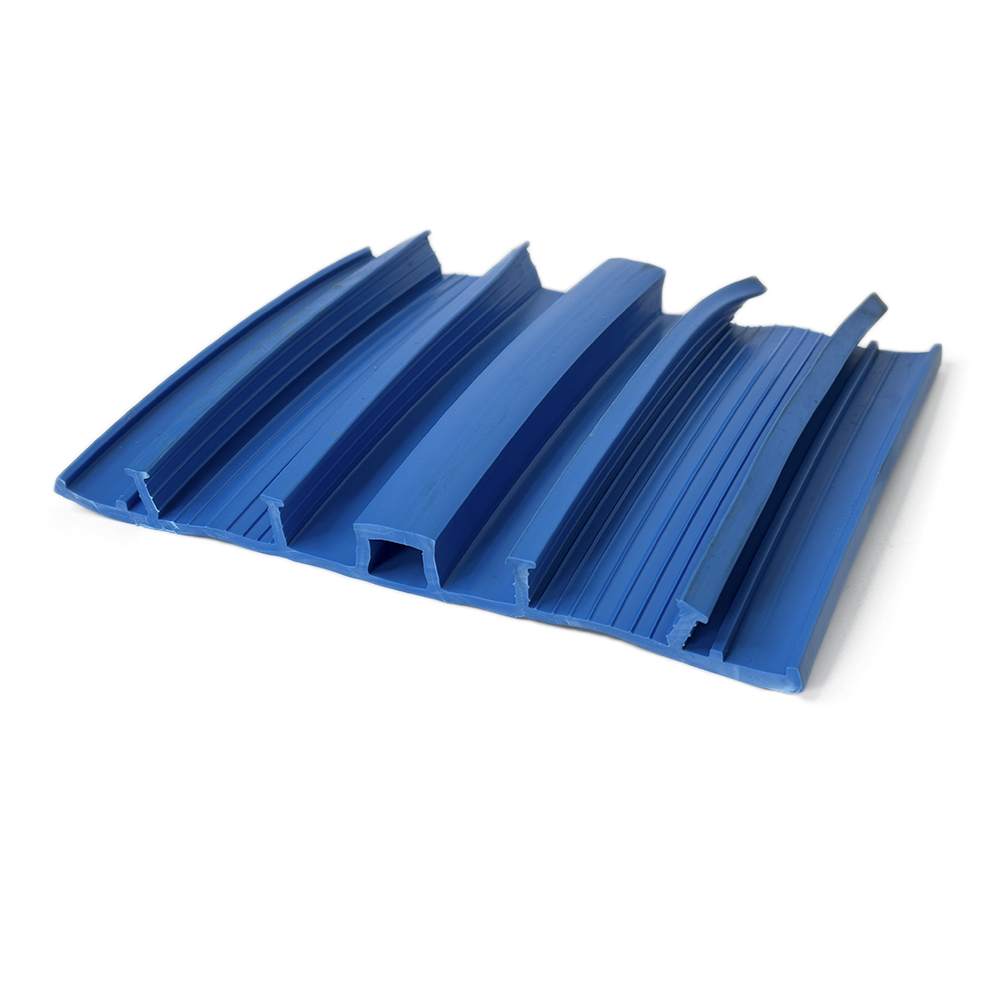

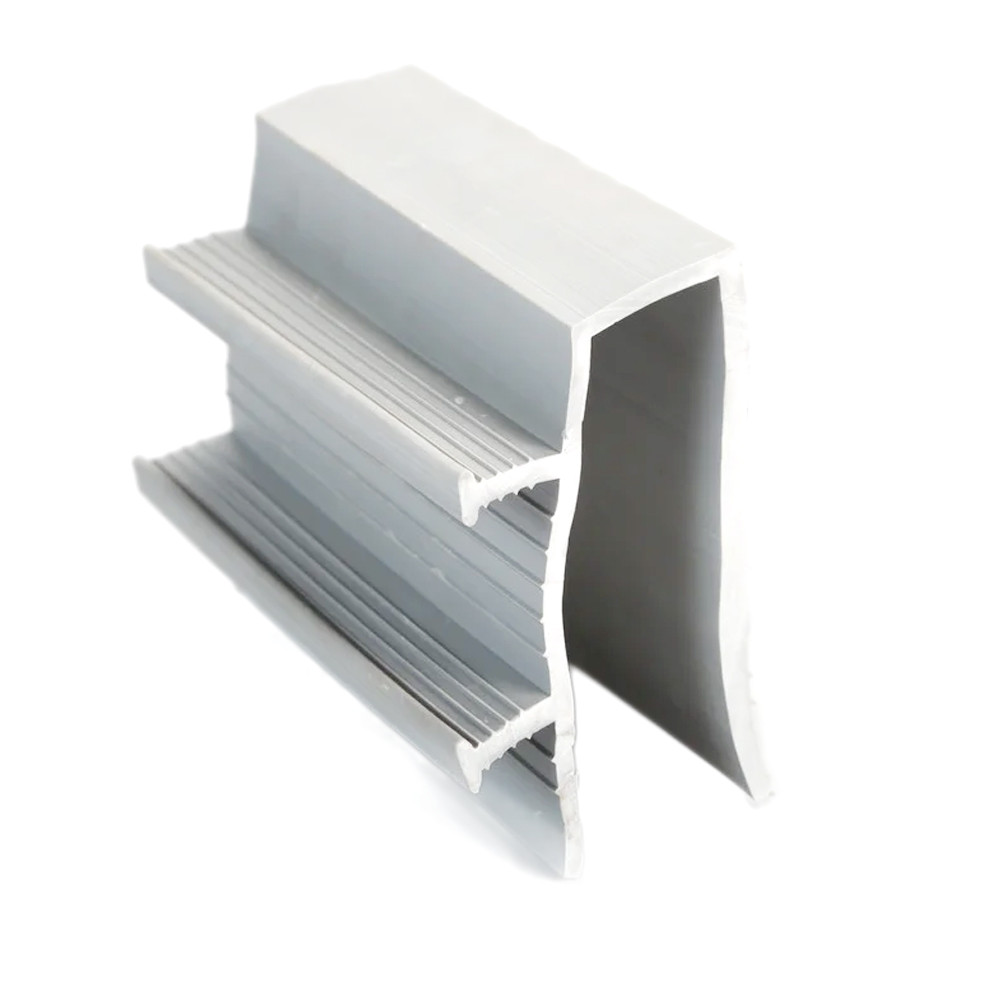

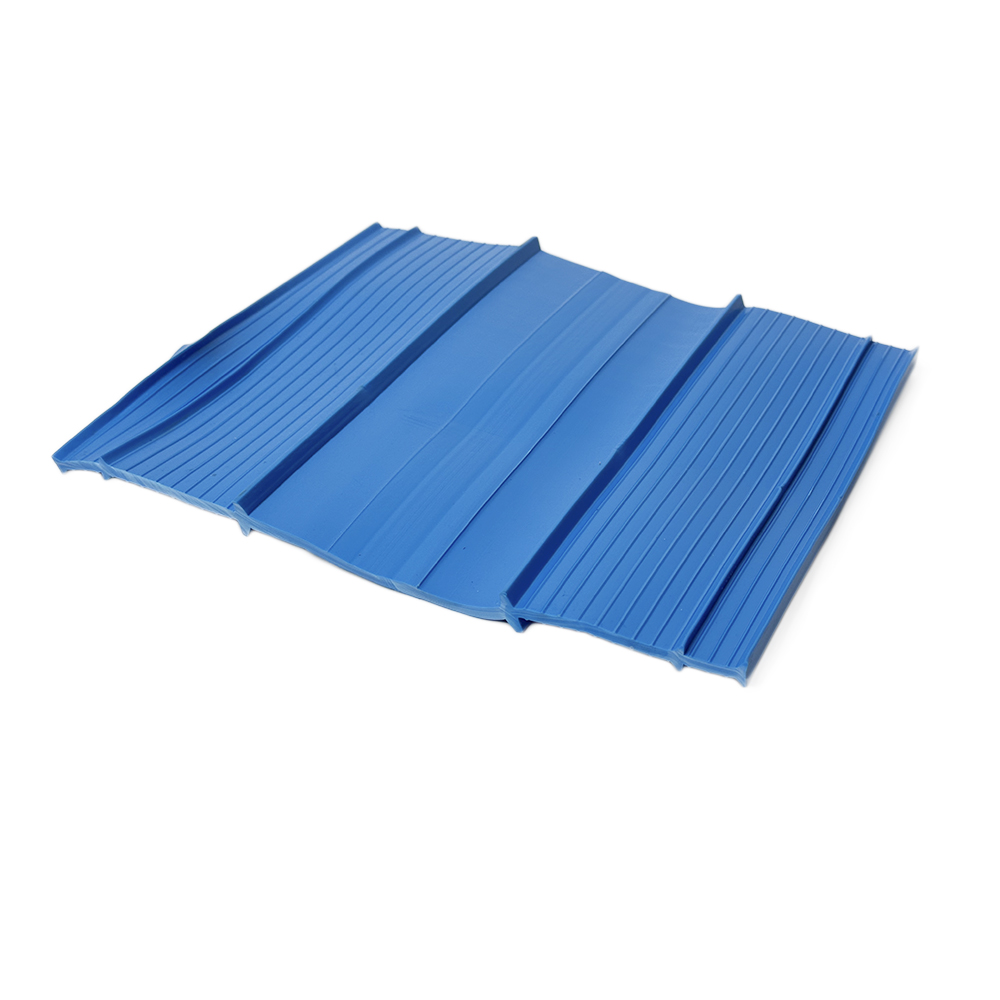

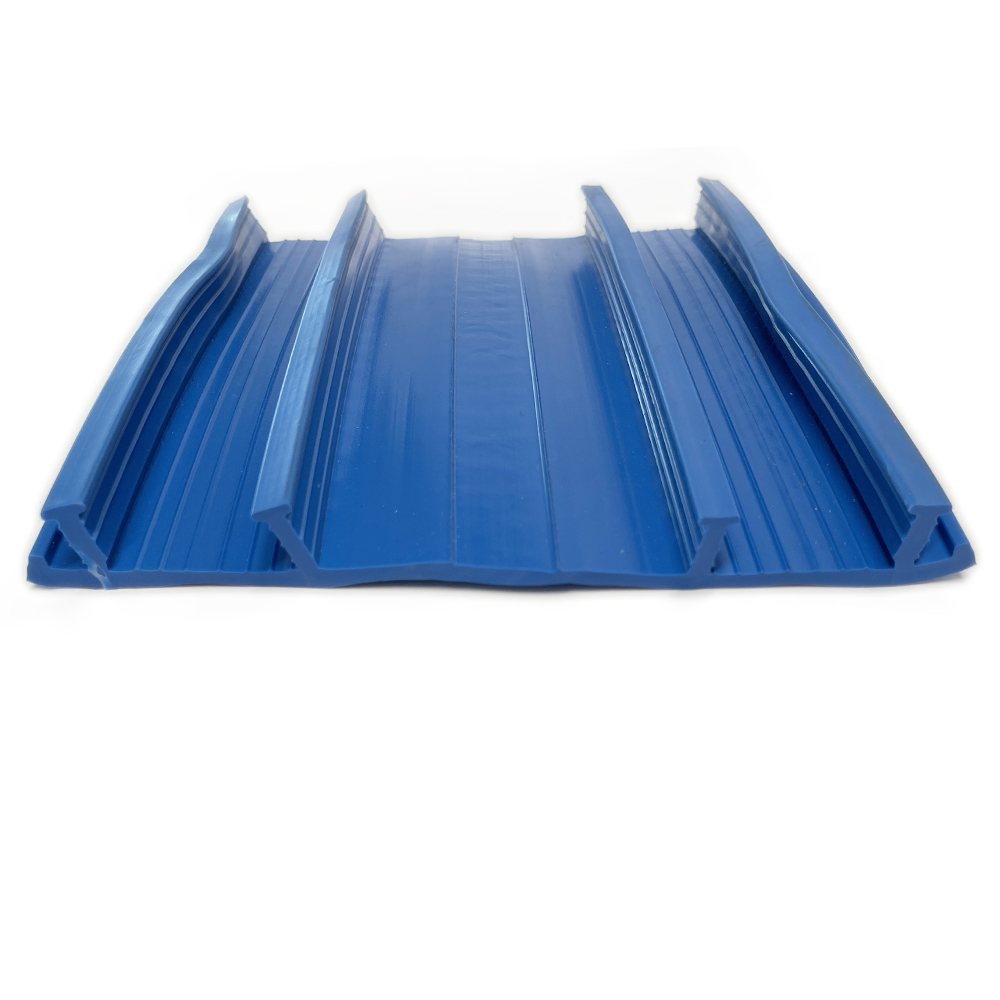

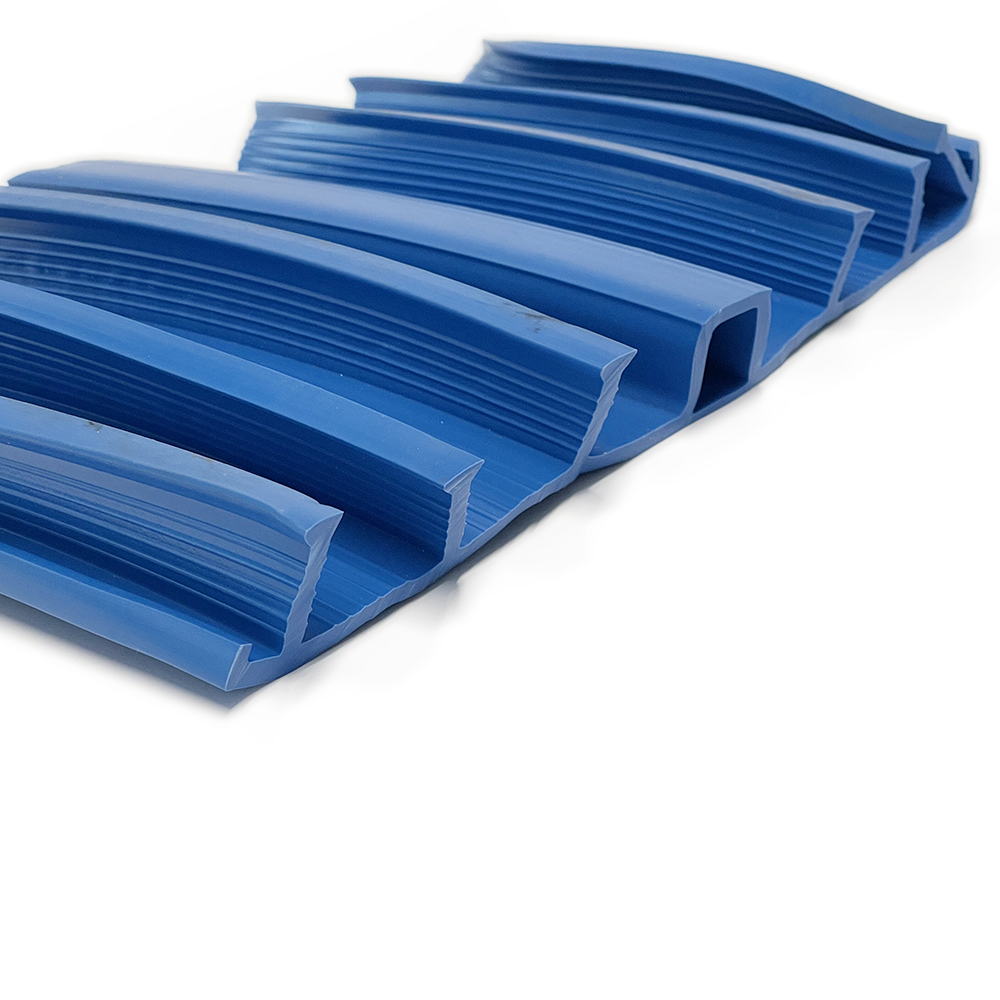

A hydro-joint (or simply a joint) is an elastic sealing tape made of plasticized PVC or modern thermoplastic elastomers (TPE). It is mounted directly into the reinforcing frame or laid on the formwork before pouring the concrete. Thus, the joint is integrated into the structure and becomes part of the monolith, ensuring tightness precisely in those places where an expansion or construction joint is provided.

Due to their flexibility and elasticity, hydro-plugs are equally well suited for objects of varying complexity. They are successfully used for sealing joints in swimming pools, tunnels, underground parking lots, in foundation slabs and walls, in places where concrete blocks are joined, as well as in pile heads in pile fields. In fact, any place where a concrete structure may be exposed to water requires reliable protection with a hydro-plug.

The main function of this material is to create a durable barrier to water penetration. A high-quality hydro-key withstands the pressure of a water column up to 75 meters high, which makes it an effective solution even in complex hydraulic structures. It is important that the key retains its properties in various climatic conditions: from frost to -10 °C and to heat above +60 °C. This allows it to be used both in cold regions and in areas with high summer temperatures.

In addition to sealing, waterstops also perform a structural function. They compensate for movements and stresses that occur in the concrete due to shrinkage, temperature fluctuations or other external factors. This means that even in expansion joints that are in constant motion, tightness will be maintained.

The advantages of hydraulic dowels are obvious:

-

Reliability and durability. With proper installation, the key retains its properties for decades.

-

Versatility of application. Suitable for both construction and expansion joints.

-

Resistance to aggressive environments. The material is not destroyed by moisture, chemicals or groundwater.

-

Easy integration into the structure. It is installed at the concreting stage, which eliminates the need for additional work after construction is completed.

Thus, sealing joints with hydro-dowels is not just an effective, but also a strategically correct solution that allows you to protect the structure from premature destruction and ensure its safe operation for many years.