Internal water -hen

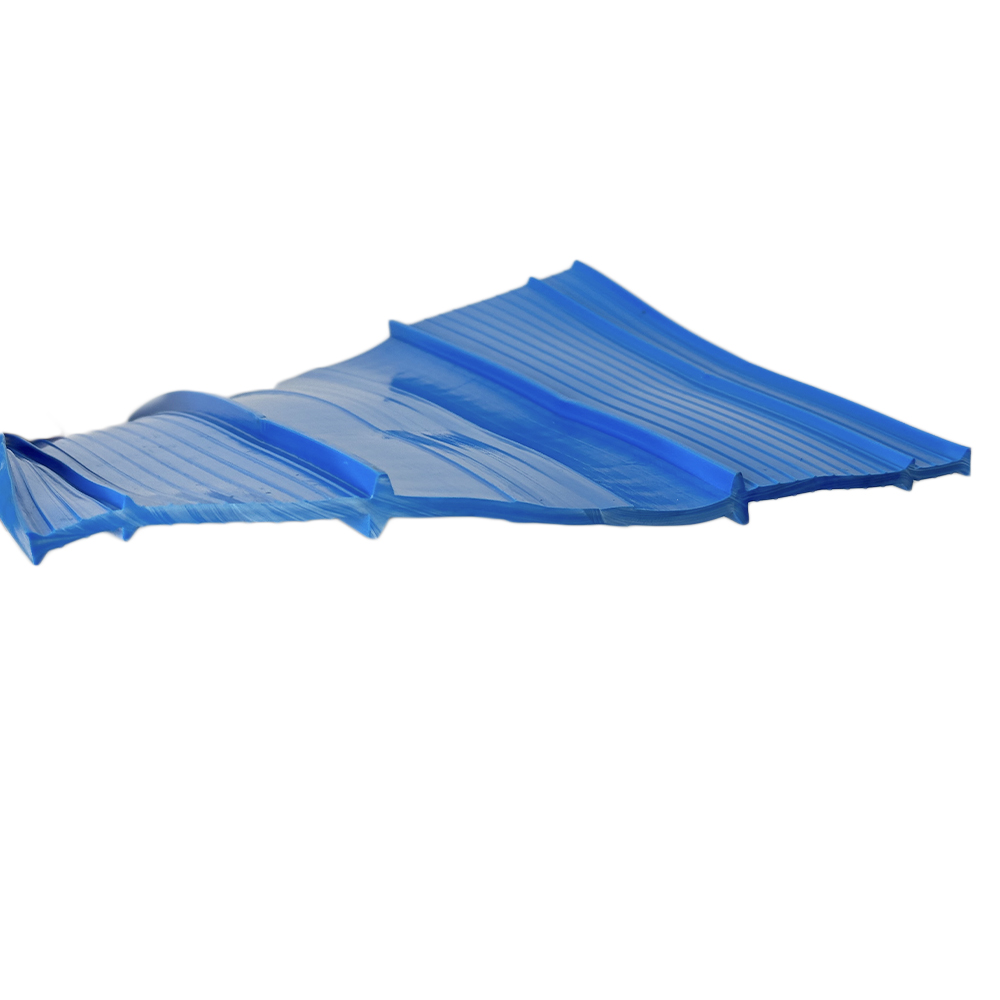

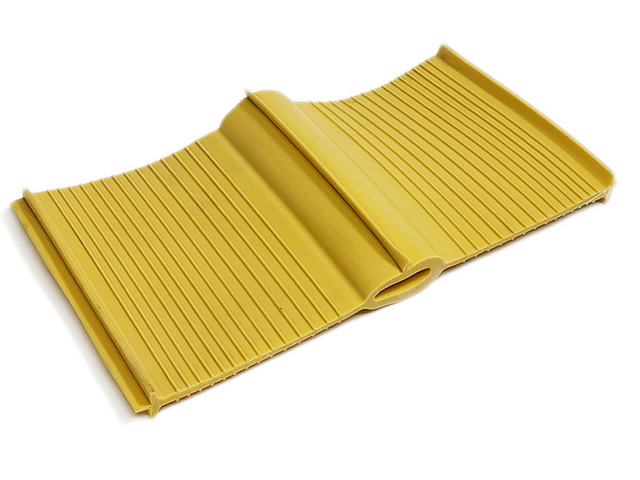

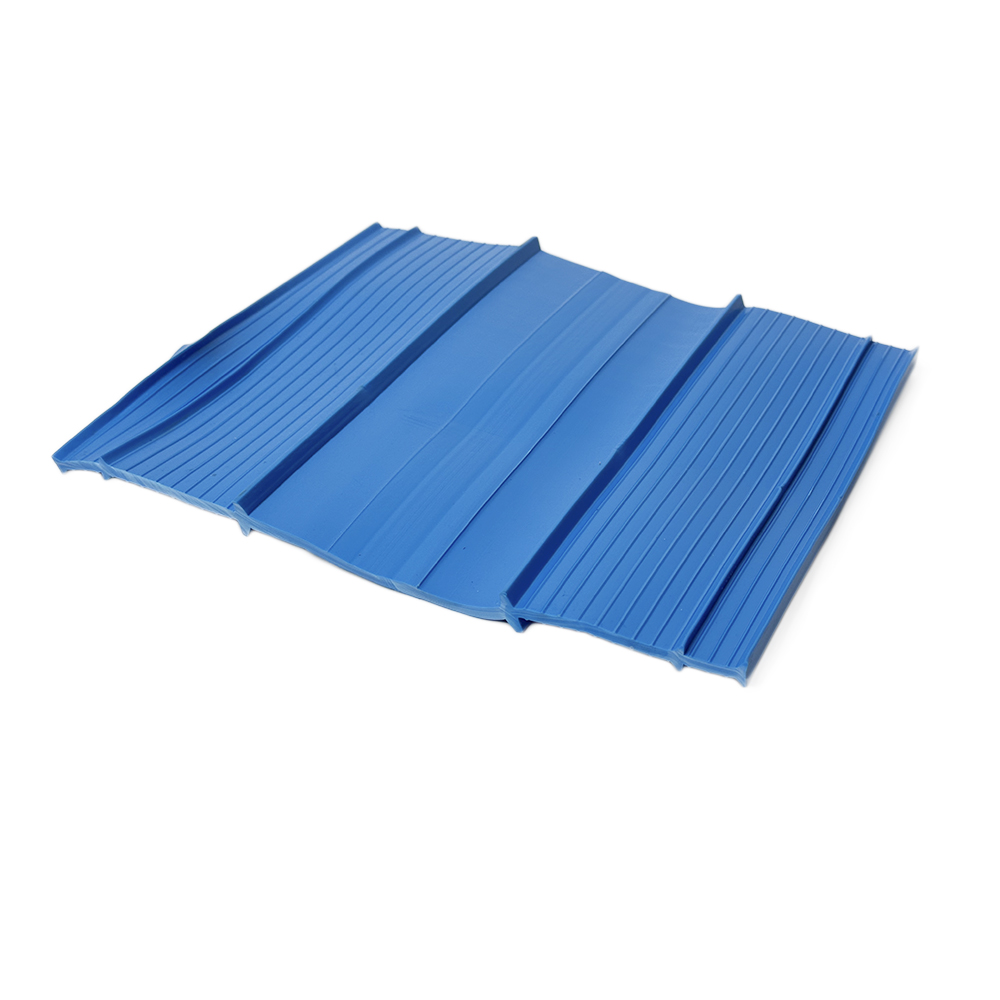

The BP series of waterstops are specially designed for sealing technological (working or cold) joints during the construction of monolithic structures. Thanks to their unique shape, the presence of locking ribs and high-quality material, these waterstops guarantee complete watertightness in the joints even under significant hydrostatic pressure.

Where are internal hydraulic anchors used?

BP series hydraulic anchors are actively used in construction:

-

foundations of residential and commercial buildings;

-

underground parking lots and parking lots under shopping centers;

-

channels, collectors, water catchments;

-

tunnels, tanks, pools;

-

industrial buildings and structures.

This is an indispensable element in cases where concrete structures are prone to the appearance of technological joints that are formed as a result of staged concreting.

Features of internal hydraulic keys BP

The BP waterproofing strip is an internal waterproofing strip that is placed directly inside the concrete structure at the intended joint location. Thanks to this, it:

-

prevents moisture from penetrating through the seam;

-

distributes water pressure;

-

preserves the integrity and tightness of the structure for decades.

Hydro plugs are made of elastic PVC , a material that provides a long service life and high resistance to moisture, temperature fluctuations, and chemicals.

Why choose BP series hydraulic wedges ?

Reliable fixation - thanks to the anchor ribs, the hydraulic dowel is firmly held in the concrete and does not shift during the pouring process.

Wide temperature range - the material retains its properties at temperatures from -40°C to +70°C.

Chemical resistance - withstands aggressive environments, such as groundwater with a high content of salts, alkalis, and acids.

High level of tightness - withstands significant water pressure both inside and outside the structure.

Environmental safety - the hydro-wedge does not emit toxic substances and does not harm the environment.

Durability - service life up to 25 years or more with proper installation.

Characteristics of BP series hydraulic dowels

| Model | Width, mm | Thickness, mm |

|---|---|---|

| BP 200 | 200 | 4.0 |

| BP 240 | 240 | 4.0 |

| BP 320 | 320 | 4.5 |

The choice of a specific model depends on the design loads, structural thickness and operating conditions.

Installation of internal hydraulic dowels BP

The installation of BP hydraulic dowels is carried out before pouring concrete . They are fixed on the reinforcing frame by

using mounting wire or special fasteners, which guarantees correct location in the concrete. Particular attention should be paid to the joining of individual elements - for this, thermal welding using mounting cords and electric heaters is used.

Order BP hydraulic wedges in Ukraine

Our assortment includes BP hydraulic dowels of our own production by Protex (Ukraine) , as well as products by Forbuild (Poland) and Arfen (Turkey) .