Installation of spiked membrane on vertical surfaces

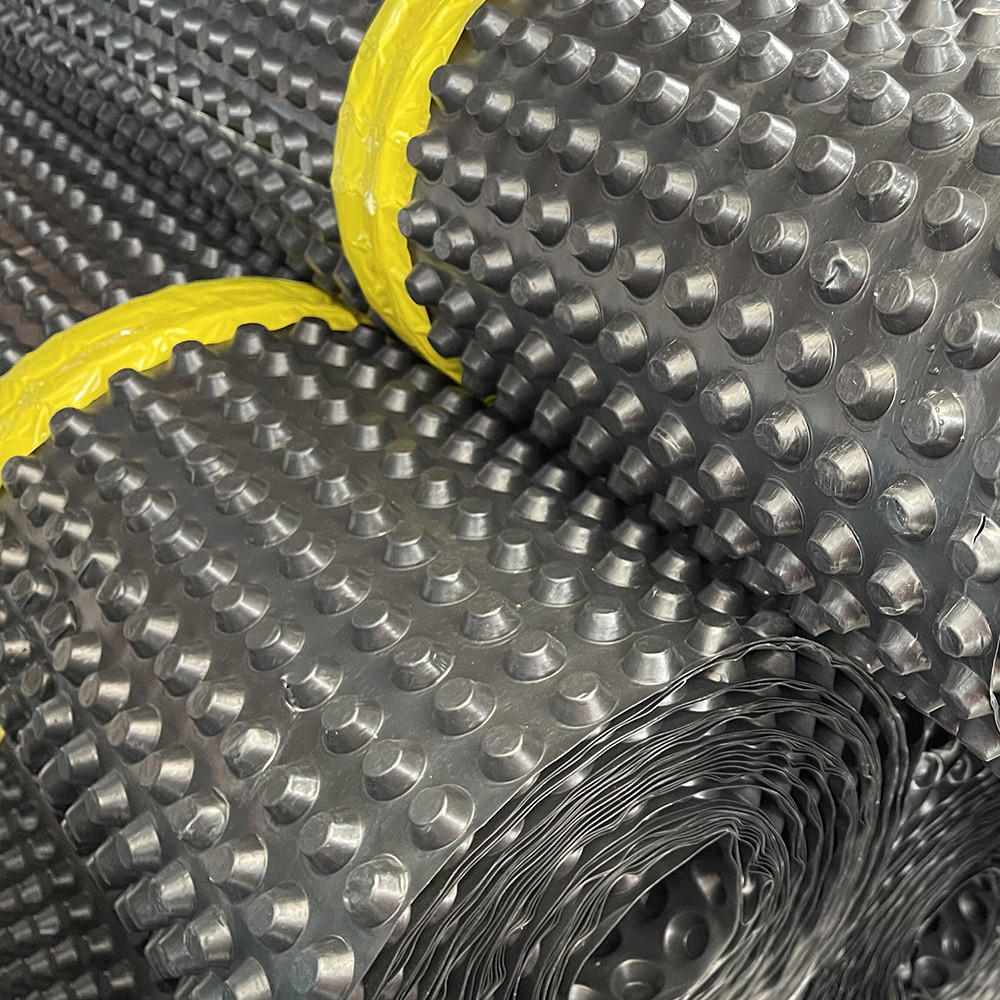

A spiked membrane is an effective solution for protecting the waterproofing of foundations, basements and basement floors from mechanical damage, moisture and soil pressure. Proper installation of the membrane directly affects the durability of the entire structure.

Depending on the operating conditions and loads , a spiked membrane with a density of 400, 500 or 600 g/m² is used, as well as a spiked membrane with geotextile for organizing wall drainage.

Installation of a spiked membrane on vertical surfaces

Installation of a spiked membrane on vertical surfaces

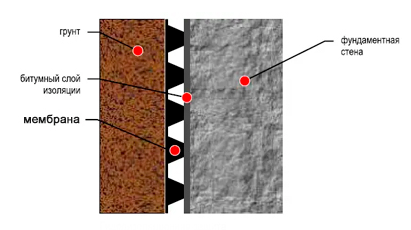

For vertical installation (foundations, basements, retaining walls), the membrane roll is installed with spikes to the wall . The material is mounted directly on compression-resistant waterproofing or on thermal insulation boards.

The rolls of the spiked membrane must protrude above the upper edge of the waterproofing by at least 10 cm - this ensures reliable and safe fastening.

If the installation is carried out over insulation located along the perimeter of the foundation, it is recommended to chamfer the upper edges of the thermal insulation boards . After that, the membrane is stretched over the edge of the insulation and fixed to the wall.

Fastening the spiked membrane

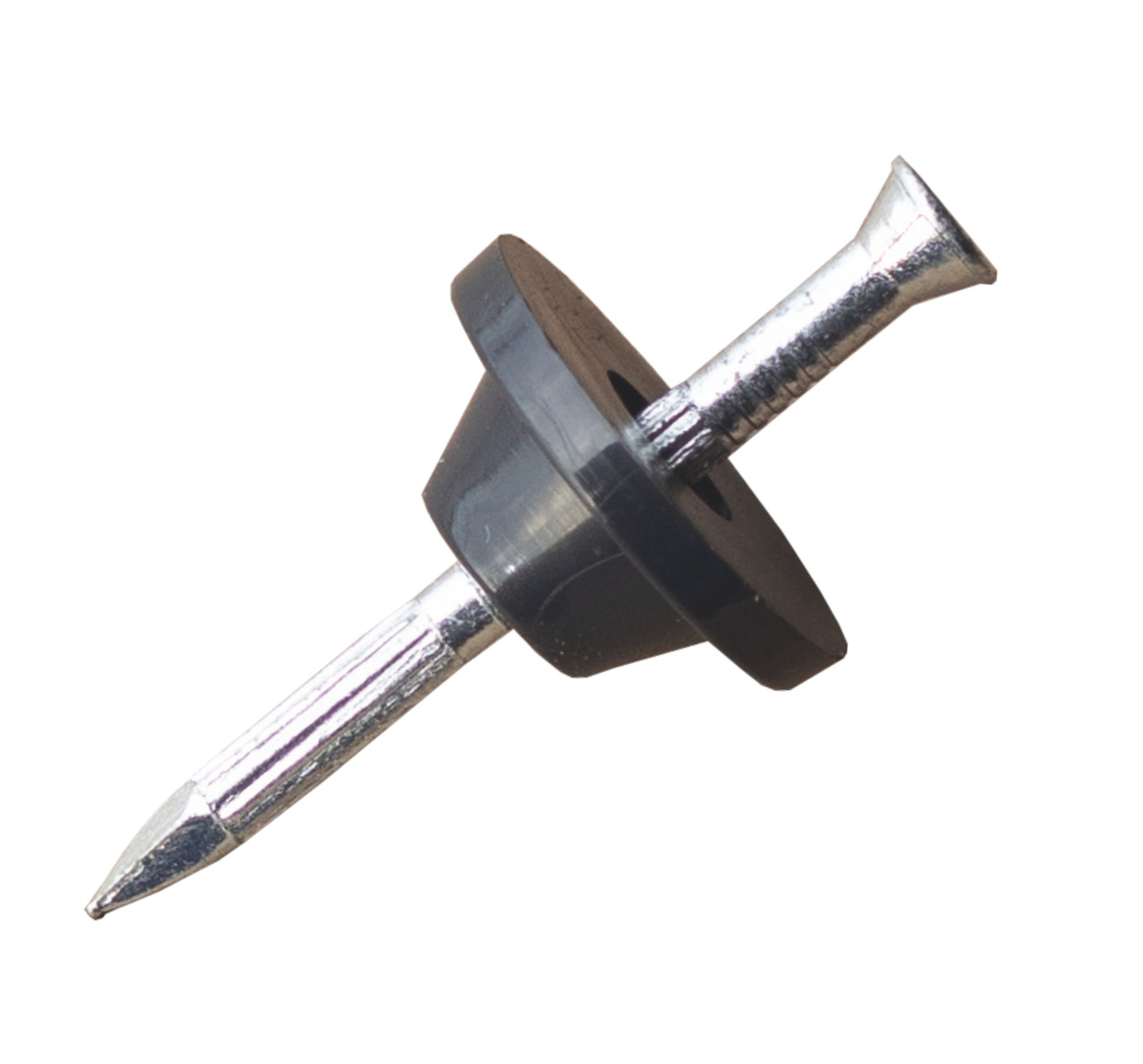

The membrane is attached mechanically :

-

nails with a wide hat or with washers;

-

special plastic dowels - in cases where the base does not allow the use of nails.

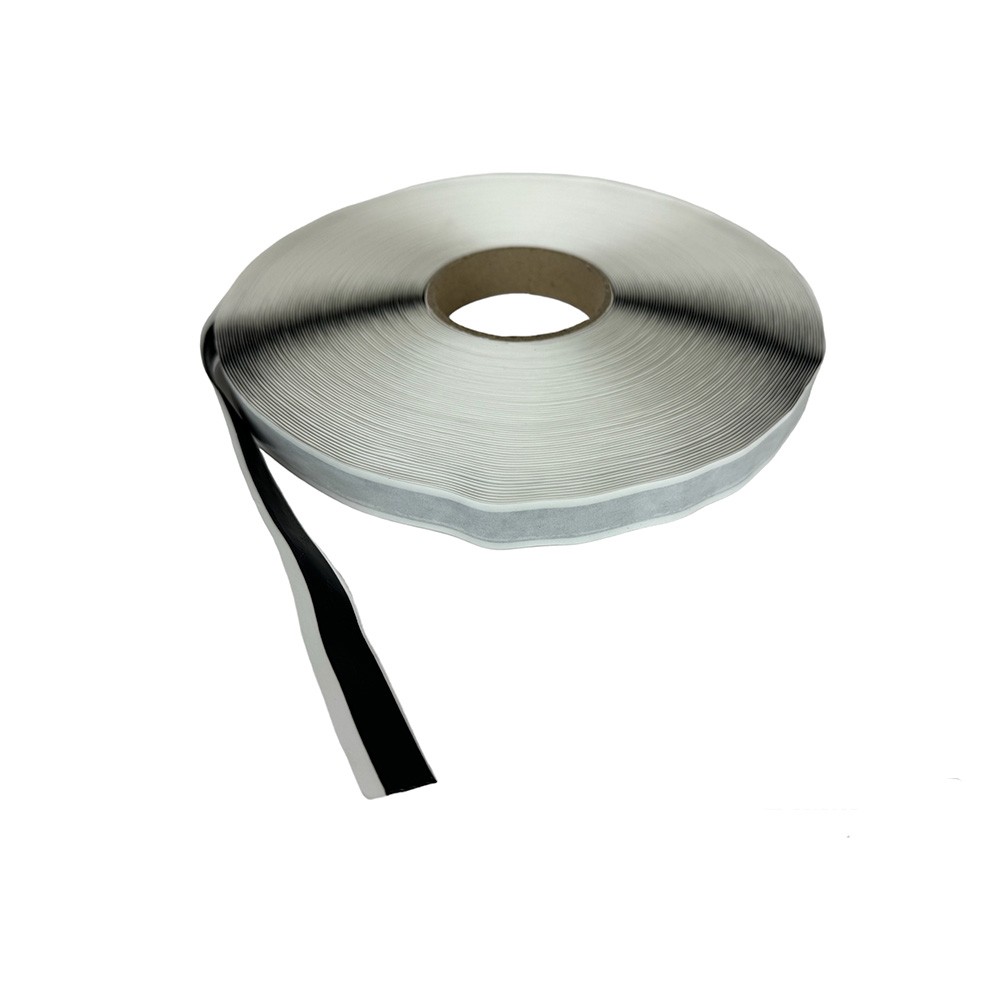

For a hermetic connection of the sheets, the membrane is laid with an overlap of approximately 20 cm , and the joint area is necessarily glued with butyl rubber tape . This approach prevents moisture and soil from entering between the layers.

Completion of installation and backfilling

The rolls of the spiked membrane must end at the level of the foundation base . Backfilling is carried out in layers with mandatory compaction of each soil layer .

After the backfill is complete, the membrane is cut parallel to the ground surface, and the upper edge is closed with a clamping strip .

Press bar:

-

protects the gap between the membrane and waterproofing;

-

prevents the ingress of stones and construction debris;

-

reduces the risk of mechanical damage to the waterproofing layer.

Installation at corners and communication passages

Before laying the membrane on the inner and outer corners, the roll is pre-bent along the corner line. The distance from the corner to the edge of the roll must be at least 1 meter .

The holes for pipes and cables are made in the form of a V-shaped cutout , after which a patch measuring approximately 30×30 cm is installed, fixing it with fasteners and additionally sealing it with mounting glue.

Correctly installed studded membrane with a density of 400, 500 or 600 g/m² , using studded membrane with geotextile , butyl rubber tape , nails and clamping bar guarantees:

-

reliable waterproofing protection;

-

effective drainage;

-

long service life of the foundation and underground structures.