PolyexMesh fiber 24 mm

For reinforcement, improvement of mechanical properties and durability of concrete

330 uah

Polyex Mesh - twisted synthetic fibers created for the purpose of reinforcement, improving the mechanical properties and durability of concrete. Polyex Mesh is a fiber consisting of a special mixture of co-polymer and polypropylene. They create reinforcement in three dimensions, which reduces or completely eliminates plastic shrinkage of concrete, is a replacement for reinforcement with steel fibers, light rods and anti-shrink nets.filling on a ground base, in the production of concrete, trays, drainage systems, tanks (with drinking water), swimming pools, elements of enclosing structures, shotcrete, etc. concrete of class from B-5 to B-100. Polyex Mesh fibers are used for the production of structural fiber reinforced concrete with improved properties compared to steel fiber reinforced concrete.

- countering the formation of shrinkage cracks

- increasing resistance to weather factors

- reduced seepage; better workability

- increased flexural strength; increased durability

- increased impact strength

- a substitute for steel anti-shrink nets in floors

- concrete industrial self-leveling floors

- road and bridge coverings

- devices of cement-sand floor screed

- outdoor areas, parking lots

- concrete slabs, foundations

- monolithic structures, reinforced concrete piles, concrete columns

- building mortars, dry mixes and plasters

- casting of small architectural forms from concrete

|

Material |

copolymer/polypropylene |

|

Form |

monofilament/fibrils |

|

Density |

0.91 kg/dm 3 |

|

Length |

24/38/54 mm |

|

Diameter |

0.069 mm |

|

Length/diameter ratio |

347/551/782 |

|

linear density |

3020 |

|

Endurance |

620 – 758 MPa |

|

Resistance to chemicals |

full |

Polyex Mesh 24 mm polymer fiber is an additive in concrete that increases the tensile, compressive and bending strength, as well as the impact strength of the structure. These are synthetic fibers that create reinforcement in three dimensions, created for the purpose of reinforcement, improving the mechanical properties and durability of concrete.Polymer fiber prevents the spread of cracks in the concrete body and simplifies the laying of the finished mixture. It works great as an alternative to metal fiber, since polymer fiber is much more convenient to use. It is evenly distributed in the concrete body and contributes to full-fledged micro-reinforcement.

Application:

- industrial self-leveling floors

- plastic cement-sand solutions

- the device of cement-sand floor screed

- a substitute for steel anti-shrink nets in floors

- outdoor platforms

- parking lots

- concrete floor slabs

- foundations

- monolithic structures

- reinforced concrete piles

- concrete columns

- building solutions

- dry mixes and plasters

- casting of small architectural forms from concrete

Features:

- countering the formation of shrinkage cracks

- increasing resistance to weather factors

- reduced seepage; better workability

- increased flexural strength; increased durability

- increased impact strength

The dosage of polymer fiber depends on the purpose of concrete (composite): 1-3kg of dry fiber per 1 m3 of concrete. This ratio makes it possible to obtain excellent quality concrete, preventing plastic shrinkage as much as possible. In comparison with iron fiber, which needs 20-40kg per 1 m3 of concrete, polymer fiber is much more economical and practical to use.

If necessary, in some cases, the amount of polymer fiber can be increased to 0.5% of the total volume of concrete

Related materials

Related materials

PROTEX superplasticizer (1kub.m barrel)

For the manufacture of concrete products and structures

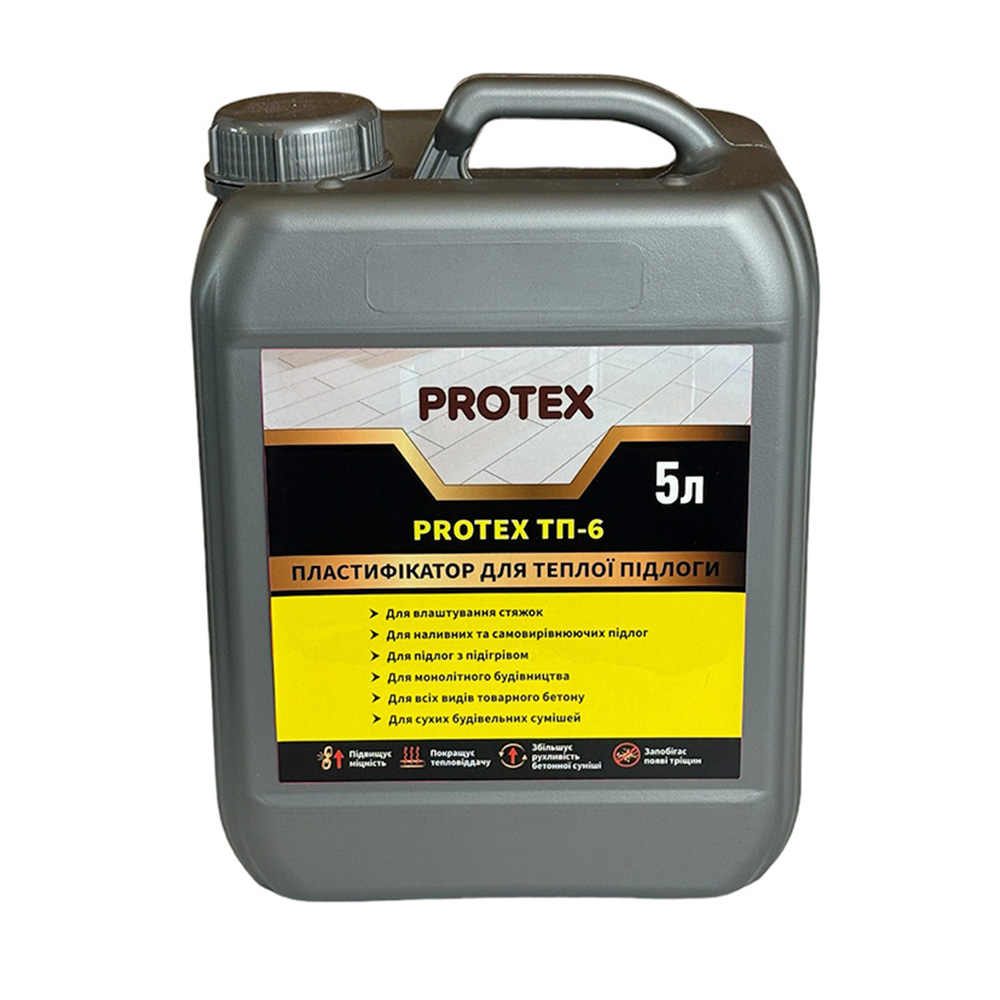

Plasticizer for underfloor heating SANPOL TP-6 5L

Additive for the manufacture of monolithic structures, the arrangement of underfloor heating and the manufacture of concrete products

Plasticizer for all types of concrete SANPOL-7 5L

Complex additive for concrete and mortar mixtures based on polycarboxylate

Antifreeze additive NITKAL S45

Antifreeze additive for concrete up to -25

PolyexMesh fiber 54 mm

For reinforcement, improvement of mechanical properties and durability of concrete

Polypropylene fiber 12 mm

Polypropylene fiber for micro-reinforcement of concrete

PolyexMesh fiber 38 mm

For reinforcement, improvement of mechanical properties and durability of concrete

© "Protex-S" LLC2021 | Website created by MD Design