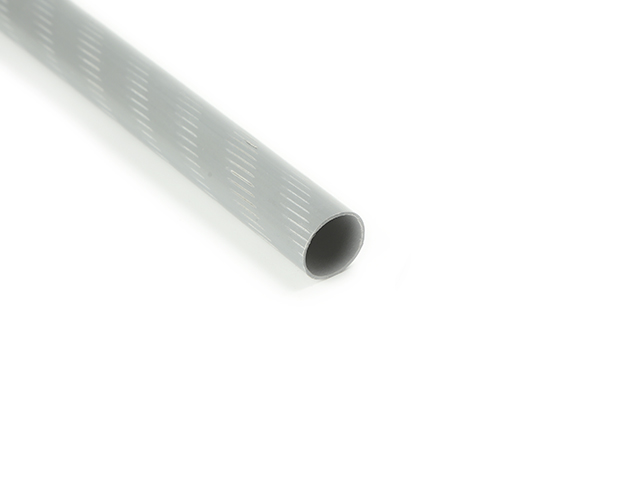

Round bentonite cord d 22 mm for sealing holes in building structures, coils of 5 meters

Product code: 0113

For sealing holes in building structures

195 uah

Waterproofing bentonite cord "Gidrostop RED" round 22mm is a material designed to provide waterproofness and seal holes after removal of the tension screw. During the installation process, before pouring concrete, a plastic PE tube d22 is inserted into the formwork, which contains a tension screw for tightening the formwork panels. After stripping, when removing the tension screw from the tube, it is necessary to close the hole. Round bentonite cord is ideal for sealing holes that remain in the concrete, after which the edge is sealed with waterproofing solution. The installation system is very simple. When in contact with water, bentonite cord significantly increases its volume. The resulting gel in a confined space creates tension that reduces water permeability, even in the presence of cracks and porous places in the concrete. Excellent technological performance and a simple installation method make it possible to use the product as an insulating material for sealing holes in underground construction, hydraulic structures and civil engineering. The bentonite cord "Gidrostop RED" has a diameter of 22 mm and is used in monolithic construction to seal holes for the tension screw. Made from bentonite clay, it swells upon contact with water and increases in volume by 4 times. The bentonite cord adheres reliably and firmly to the concrete surface, filling seams, junctions and even the smallest voids in the concrete body, forming a reliable protective layer.

- excellent technological performance

- easy installation method

- the ability to use the product as an insulating material

- for sealing holes for clamping screws

- use on hydraulic structures

- use in civil engineering

- Sold in boxes of 5 l.p.

Density, g/cm3: 1.5

Color : Red

Packaging: Rolls of 5 m

Boxes: 40 m each (8 rolls)

Flexibility on beam with radius R=25 mm:

at a temperature of minus 30 °C: no cracks

at a temperature of plus 50 °C: no cracks

Volume expansion after exposure to water, %

-after 24 hours: 25

-after 48 hours: 80

-after 7 days: 210

Tensile tensile strength, N, not less: 18

Elongation at break, % not less than: 25

Bentonite cord Hydrostop SANPOL round with a diameter of 22 mm in combination with the repair mixture Teknorep 300EX provides reliable sealing of holes from tension screws in concrete structures.

The sealing process is as follows:

Hole preparation:

Keep holes free of dust, dirt and other contaminants to ensure better adhesion between materials.

Preparation of bentonite cord:

Cut the bentonite cord 10 cm shorter than the thickness of the formwork. Make sure the cord is the right diameter for the hole.

Installation of bentonite cord:

Insert bentonite cord into the hole until it fills the voids around the screw and provides a good seal.

Sealing holes with repair mixture:

Use Teknorep 300EX Thixotropic Repair Compound to seal holes. Apply it on both sides of the hole to ensure the bentonite cord is completely filled and securely held.

Application of Teknorep 300EX:

Ensure that Teknorep 300EX is applied evenly and tightly, providing good adhesion to the concrete and creating an additional protective layer around the hole.

Using sand-cement mortar to seal holes, as mentioned, can cause problems in the long run due to shrinkage, cracks and sealing failures. Therefore, the use of specialized materials such as bentonite cord and Teknorep 300EX is preferred to ensure durability and reliability of the structure.

What is the method of laying and installing bentonite cord?

Installation of a bentonite cord depends on its type and is done using a special mesh, sealant or glue. To achieve complete compaction and insulation from moisture, a bentonite strand "Hydrostop RED" in the form of a tape is installed in the cold seams of foundations and walls using steel nails every 30-40 cm to avoid displacement and to provide a better connection with the concrete. During installation, it is necessary to prevent disruption of the continuity of the tape position.

How to choose the right bentonite cord?

To seal technological seams, the size of the bentonite cord is selected depending on the thickness of the concrete wall or slab and the technological characteristics of the structure.

- for sealing holes - bentonite cord with a round cut with a diameter of 22 mm.

- for communication inputs - rectangular cut 5x20 mm.

- for sealing cold seams - a rectangular cut 10x20; 15x25; 20x30 mm.

How is bentonite cord of round cut applied?

The bentonite cord of the round section d22 is inserted into the hole after the coupling screw and covered with a repair mixture.

What is the principle of operation of bentonite cord?

Bentonite cord securely and firmly adheres to the concrete surface, filling seams, junctions and the slightest voids in the concrete body, forming a reliable protective layer. The principle of operation is that as a result of hydration, the bentonite cord increases in volume, forming a gel-like mass that fills all cracks and voids and reliably seals the seams of the concrete structure. The cord expands 4 times in the concrete body.

Related materials

Tension screw for tightening formwork panels, plywood, OSB, 3 m

Screed screw for screed boards of formwork, plywood, OSB

Retainer Cone

Locking cone to protect the formwork elements from the impact of concrete

Pipe P/E d-25 segments 2m

Pressure pipes for the construction and reconstruction of external pipelines

Polyethylene construction film 100 microns sleeve 300kv.m

Universal construction film

© "Protex-S" LLC2021 | Website created by MD Design