Internal hydraulic gasket for working seams BP 200, PVC, blue, bay 20 m

Product code: 0071

Internal hydraulic joint for working seams

292 uah

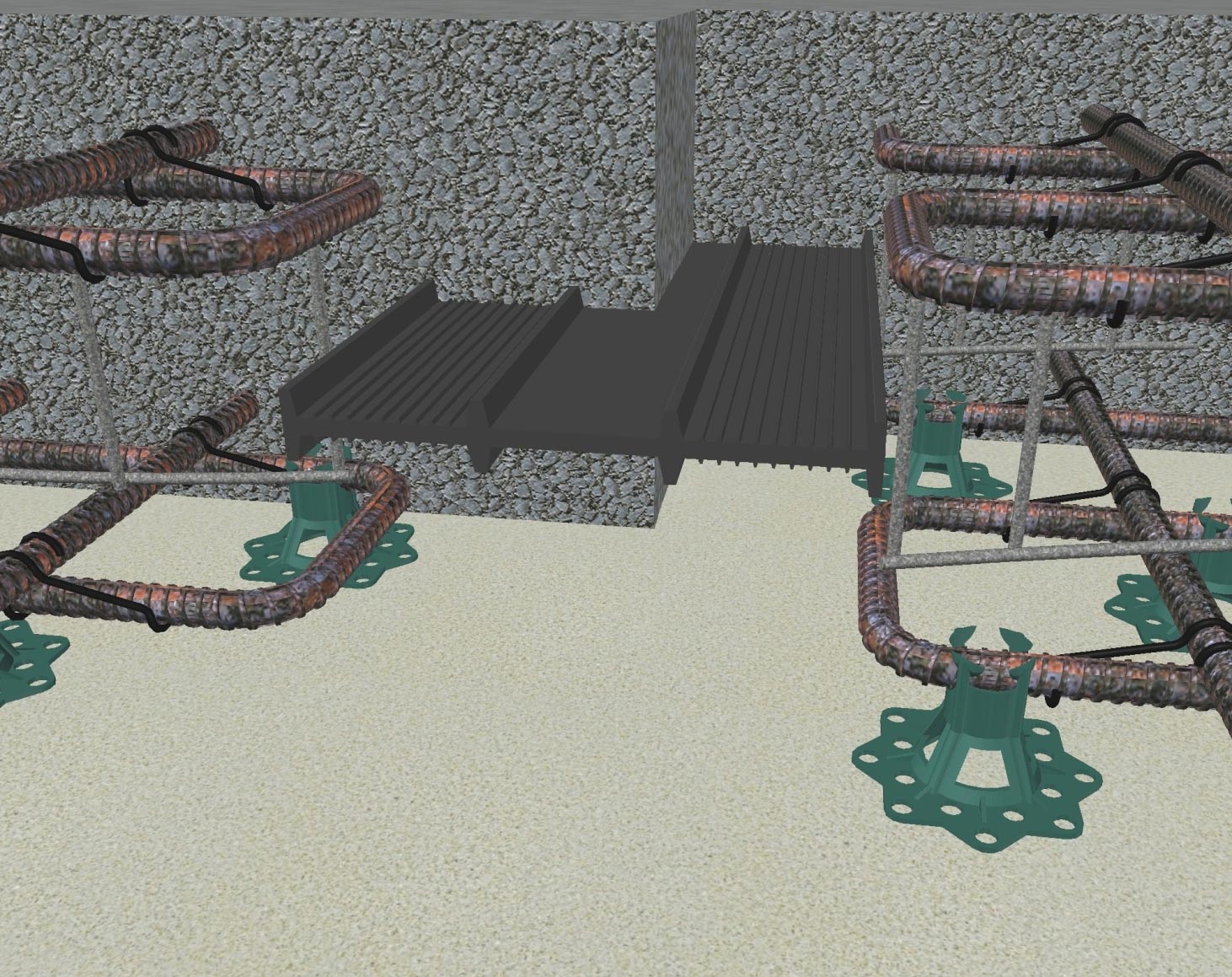

The BP 200 hydraulic shingles are designed for waterproofing working (technological) joints of concrete structures between a horizontal base plate and a vertical load-bearing wall, or formed during a break in concreting. Hydraulic dowels are used in hydraulic structures: reservoirs, channels, dams, pools, etc., as well as for waterproofing joints of foundations, foundations, tunnels, multi-level parking lots and other underground structures. They are made of plasticized PVC-p polyvinyl chloride.

- It is used when concreting monolithic reinforced concrete structures is interrupted

- in particularly important structures, it is complemented by an external hydraulic gasket

- the presence of ribs on the locking plane prevents moisture from entering the structure

- It can be used in structures with special requirements to ensure tightness

- withstands high water pressure inside and outside

- with ease of installation, it is suitable for all types of structures

- It is supplied in rolls of 20 m.p.

Material : Plasticized polyvinyl chloride (PVC-p)

Color : Blue

Packaging: Rolls of 20 m.p.

Roll length deviation, m,: no more than ± 0.5

Size Deviation : According to CD

Shore hardness, A : 70 ± 5

Density, g/cm3 : ≈ 1.4

Tensile strength, MPa : ≥10 (DIN 53455)

Elongation at break, % : ≥ 275

Temperature resistance, °C : from -35°C to 70°C

Chemical resistance :

- from constant exposure to water and wastewater;

- from short-term exposure to inorganic alkalis and low concentration acids, mineral oils.

UV resistance : Not resistant

Service life : 25 years

The BP 200 hydraulic gasket is an ideal solution for waterproofing the working joints of concrete structures. Thanks to it, you can provide reliable protection against moisture penetration between the horizontal base plate and the vertical load-bearing wall, as well as waterproofing breaks in concreting. Our hydraulic shutters are made of plasticized PVC-p polyvinyl chloride. Due to this, they withstand high water pressure, both inside and outside. We offer rolls of BP 200 with a length of 20 meters, which will allow you to easily and conveniently use them in any desired designs. The presence of ribs on the locking plane of the hydraulic shutter guarantees reliability and protects against moisture penetration inside. Moreover, our hydraulic gasket can be used even in structures with special requirements to ensure perfect tightness. The BP 200 hydraulic shingle is used when concreting monolithic reinforced concrete structures is interrupted and can be supplemented with an external hydraulic shingle in particularly important cases. By choosing the BP 200 hydraulic gasket, you get reliability, ease of installation and the possibility of use in all types of structures.

Hydraulic gasket BP 200 is an indispensable material for waterproofing the working seams of concrete structures. It provides reliable tightness, protecting structures from moisture penetration and maintaining their strength and reliability for a long time. The use of a hydraulic shutter is widespread in hydraulic structures such as reservoirs, canals, dams and pools. It is also ideal for waterproofing joints of foundations, foundations, tunnels and multi-level parking lots. The BP 200 hydraulic shutter is made of plasticized PVC-p polyvinyl chloride, which ensures its strength and durability. It withstands high water pressure and protects structures from both the inside and outside. The installation of the BP 200 hydraulic shutter is very simple and can be performed on various types of structures. It has ribs on the locking plane that prevent moisture penetration, which makes it an ideal choice for particularly important structures. In addition, it is supplied in rolls of 20 meters, which makes it convenient for transportation and installation. The BP 200 hydraulic gasket is a reliable solution for waterproofing and protecting your concrete structures.

How do I install a hydraulic shutter?

The hydraulic shutter is installed in the design position, so that the middle of the hydraulic shutter is located in the center of the intended seam.

The fastening is made directly to the formwork. Holes for fasteners are allowed to be made only in the extreme zone of the hydraulic gasket, behind the extreme anchor. The mounting pitch is 200-300 mm, symmetrically on both sides. Additional fastening is also performed to the reinforcement frame with knitting wire. The connection of the key is made by welding, by heating the ends of the key in a special conductor (for each key there is an individual conductor) or using an industrial hair dryer or a flat heating element. The temperature of the spike is about 200 ° C (selected experimentally). To connect the dowels by the "cold" method, glue is used, for example, a one-component paste-like glue based on

silane modified polymer Innoellast.

Related materials

Related materials

Hydraulic joint PO-1 repair hydraulic joint for expansion joints , bay 20 m, gray

Repair hydraulic joint for expansion joints of the PO-1 series

Repair hydraulic gasket for expansion joints ND-R 200, PVC, bay 20 m, blue

Repair hydraulic joint for expansion joints

Combined hydraulic gasket for working seams KAB-150, bay 25 meters

Combined hydraulic joint for working seams KAV-150

Combined hydraulic gasket for working joints KAB-125, bay 25 meters

Combined hydraulic gasket for working joints KAV-125, bay 25m

Repair hydraulic gasket for expansion joints of the PO-3 series, bay 20 m

Repair hydraulic joint for expansion joints of the PO-3 series

Hydraulic gasket internal hydraulic gasket for expansion joints VD 240, PVC, blue, bay 20 m

Hydraulic gasket internal hydraulic gasket for expansion joints VD 240, PVC, bay 20 m

Internal hydraulic gasket for expansion joints VD 200, PVC, 20 m bay, blue

Internal hydraulic gasket for sealing and waterproofing of deformation movable joints VD 200, PVC, bay 20 m, blue color

© "Protex-S" LLC2021 | Website created by MD Design