Pouring concrete in the presence of frost requires special precautions.

Although additives such as antifreeze additives can make concrete more resistant to low temperatures, there is always a risk of water freezing in concrete, especially at lower temperatures.

If it is necessary to fill the foundation at - 5 ° C, it is recommended to take the following steps:

Antifreeze additives: Add special antifreeze additives to the concrete mix to improve its resistance to low temperatures. Such additives include the antifreeze additive for concrete NITCAL S 45

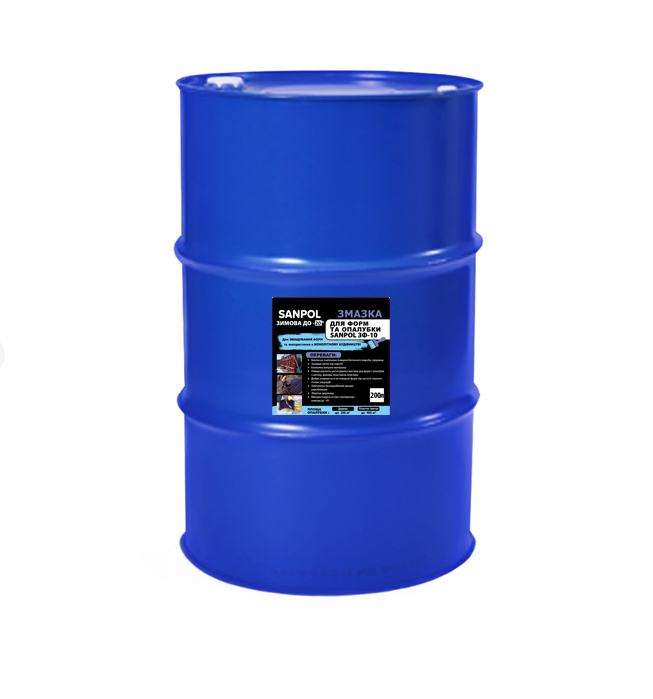

As a formwork treatment in winter, you can use ZF-10 formwork Lubricant, which can withstand air temperatures up to -20 ° C.

Concrete heating: Use heating systems or insulation around the foundation mold to maintain an optimal temperature during pouring and initial solidification of the concrete.

Cold protection: After pouring the foundation, ensure that it is protected from low temperatures by using insulation materials, films, such as 200mkm construction film, or other materials.

Planning and consulting with professionals: Discuss the foundation pouring plan with engineers and concrete specialists to ensure that the best methods and materials are selected for specific climatic conditions.

Despite the measures taken, it is recommended to avoid pouring concrete at extremely low temperatures, if possible.

Waiting for warmer conditions will ensure safer and more efficient construction, minimizing the risks of concrete damage.